The computer-based Decision Support

System (DSS) MiCorr is a new

non-invasive diagnostic tool for metal objects. Three search engines have been developed: the

first one uses interlinked keywords, the second a decision chain to identify metal families and the third digital stratigraphies of corrosion forms. The latter, based on

Bertholon’s schematic description of metal corrosion[1],

is the most innovative tool of this application. Corrosion forms are described as structures of strata (metal, corroded metal, corrosion

layers…), each stratum having its specific characteristics (morphology,

microstructure, texture and other properties). A modelling program allows to build a corrosion structure from coded building blocks (strata containing up to 30 characteristics).

The same set of analytical techniques with similar operating

conditions have been used to characterize the corrosion forms/case studies of the database. Some of them required the destructive sampling of artefacts to determine the

precise nature, organization and composition of the corresponding strata. As they are characterized with the same digital construction

model which is used for the corrosion forms under investigation a comparison becomes possible.

By comparing the corrosion form of an artefact

under observation or a sample from the same artefact observed on cross-section with the database through the DSS, a MiCorr user is able

to find case studies/corrosion forms of objects showing similar corrosion phenomena. In case the user is a conservation professional, this should help him.her to implement an appropriate conservation protocol.

The search engines allow the

user to question the database but if registered he.she has also the possibility to enrich

the database with new corrosion forms and/or case studies, thus becoming an active contributor. The

basic format of the corrosion forms can be further improved with any

additional analytical data and the operating conditions used.

In short, MiCorr aims to:

The didactic, self-learning and freely accessible and participatory MiCorr tool should enable the various scientific communities involved in the analysis and conservation of metals to better understand existing knowledge and contribute to unsolved research problems.

A thorough understanding of

alteration processes developed on metals enables us to

slow down, limit and / or stop existing corrosion. In the industrial field, sampling of metals to investigate the amount of alteration observed is not

unusual and the information gained provide knowledge on the corrosion developed such as stress corrosion cracking,

fatigue corrosion, corrosion due to exposure to high temperature or pressure which are rarely encountered in the heritage domain. If this type of alteration does appear on historic or archaeological artefacts, it will not necessarily be

similar due to the long periods of stress or alteration involved. Therefore,

the examination of contemporary metals cannot solely be used to predict the

long-term preservation of materials (Neff 2006[2]).

When conserving metal artefacts, conservation

professionals try to carry out the most precise diagnosis in order to find an

appropriate conservation treatment. This diagnosis requires a thorough description

of the surface condition of the object under investigation. Based on experience and consultation of corrosion forms published in the literature (Corrosion

Science, Studies in Conservation, Journal of Cultural Heritage, etc.), conservation professionals try to find analogies

with the observed corrosion forms. On the basis of this knowledge conservation strategies can be proposed.

But the matching between the corrosion forms

investigated and those that are used for comparison is difficult to achieve.

This is due to the lack of standardization in the description of the object

surfaces (according to his/her experience, each conservator perceives the

object in a different way) and the heterogeneity of heritage metal surfaces. The

use of different analytical tools can bring further bias in the description of

corrosion forms.

The professional associations of corrosion experts (NACE - the Professional society for

corrosion engineers since 1943 and the European Corrosion Federation since

1955) have published numerous books on metal corrosion. Although the corrosion

mechanisms under particular environmental conditions (and the means

to prevent it) are known, there are no online diagnostic tools to link

observed alterations to the causes of corrosion. Websites such as http://corrosion-doctors.org/Contents.htm provide illustrations of corrosion forms. Unlike heritage metals which show extensive and complex

corrosion forms, such as active or reactivated corrosion, they only show the

result of the reactivity of the clean metal in a corrosive environment. In the conservation domain, only one database (www.materialspathology.com) existed in the past but is no longer available. It offered descriptions of corrosion forms encountered on heritage metals, but did not provide a diagnosis.

Over the years, much

research on the diagnosis of corroded heritage metals has been carried out and regularly

published: Dillmann and his team (Dillmann 2005[3])

have been investigating the alterations of archaeological and historic iron ; Robbiola (Robbiola 1998[4])

has focused on the study of natural patinas on copper-based alloys and how they undergo changes when

buried in a chlorinated soil that favours active corrosion ; Turgoose (Turgoose

1985[5])

has investigated alterations of lead artefacts in organic acid-rich environments,

such as those found in museum display cases and storage cabinets. The outcome of all this

research is dispersed in the literature due to the different backgrounds of the

researchers involved (corrosion scientists, archaeometers, conservation

scientists) as well as the audience to which the publications are addressed to

(industry, engineering, conservation of cultural heritage).

Most of this research is based on

the study of samples taken from the core of the metal under investigation.

Until the research of Bertholon on the visual description of corrosion products

and their structure (Bertholon 20011 [6]),

it was impossible to adequately describe corrosion phenomena in a standardized way

and refer then to existing models. Some conservation training programmes such

as at HE-Arc CR, are trying to implement this method to diagnose alterations

observed on both studied and unstudied heritage metals. MiCorr is the logical

continuation of these efforts that will allow a broader community to adopt this

methodology and improve their diagnosis on heritage metals.

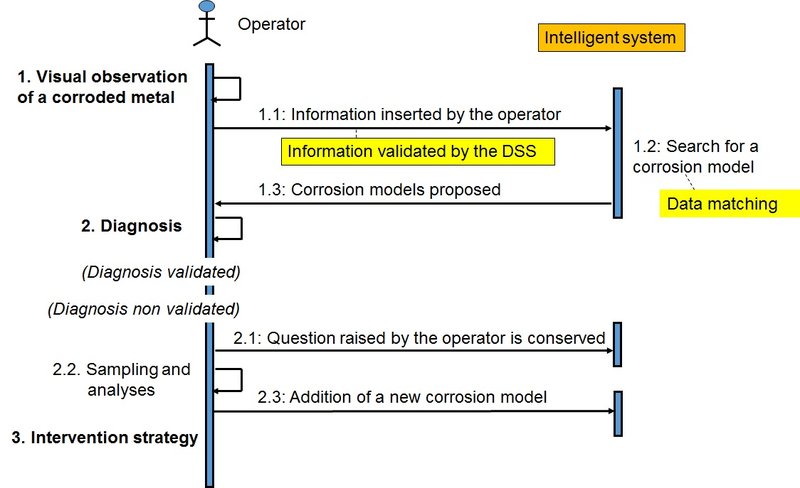

The research methodology of MiCorr follows the

steps of a conservation project. It starts with the visual observation of the

altered object, continues with the diagnosis and ends with the proposal of

conservation treatments. Figure 1 illustrates these 3 steps:

Fig. 1: Schematic representation of the research methodology.

[1] Bertholon, R. La limite de la surface d'origine des objets métalliques archéologiques, caractérisation, localisation et approche des mécanismes de conservation. UFR03 Art et Archéologie. Paris, Université Paris 1 Panthéon-Sorbonne, 2000, 419p (https://tel.archives-ouvertes.fr/tel-00331190/document).

[2] Neff, D., Bellot-Gurlet, L., Dillmann, P., Reguer, S. and Legrand, L. (2006) Raman imaging of ancient rust scales on archaeological iron artefacts for long-term atmospheric corrosion mechanisms study, J. Raman Spectrosc, 37: 1228–1237.

[3] Dillmann, P. (2005) Corrosion des objets archéologiques ferreux, Les Techniques de l’Ingénieur, AF 6920, COR675 : 1-20.

[4] Robbiola, L., Blengino, J-M., Fiaud, C. (1998) Morphology and mechanisms of formation of natural patinas on archaeological Cu-Sn alloys, Corrosion Science, 40, 12, 2083-2111.

[5] Turgoose, S. (1985) The corrosion of lead and tin: before and after excavation, in Lead and tin: Studies in Conservation and Technology, ed. C.E. Miles and S.C. Pollard, UKIC, Occasional Papers, n°3, London, 15-26.

[6] Bertholon, R. (2001) Characterization and location of the original surface of corroded archaeological objects. Surface Engineering, 17 (3), 241-245.

[7] Degrigny, C. (2012) Methodology to study and analyse the microstructures and corrosion forms of ancient and historic metals: application to metallographic samples from Swiss collections, rapport final du projet MIFAC-Métal, rapport interne, HE-Arc CR, 188p. (available from the author).

[8] Degrigny, C. and Le Gall, R. (1999) Conservation of ancient lead artefacts corroded in organic acid environments: electrolytic stabilisation / consolidation, Studies in Conservation, 44, 157-169.

[9] Degrigny, C. and Witschard, D. (2006) La chasse des enfants de Saint Sigismond de l’Abbaye de Saint-Maurice: traitements électrochimiques des reliefs en argent en cours de restauration, in Medieval reliquary shrines and precious metalwork, in Proceedings of a conference at the Musée d’Art et d’Histoire, Geneva, 12-15 September 2001, Anheuser K. and Werner, C. (eds), Archetype, 9-16.

[10] Degrigny, C. (1993) La mise au point d’un traitement cathodique de stabilisation de vestiges aéronautiques immergés en alliages d’aluminium, actes du colloque Sauvegarder le XXème siècle : la conservation des matériaux modernes, Ottawa 1991, Pub. ICC, 373-380.

[11] Degrigny C. and Schröter J. (2019) Aluminium Alloys in Swiss Public Collections: Identification and Development of Diagnostic Tools to Assess Their Condition, in METAL 2019, proceedings of the ICOM-CC Metal WG interim meeting, eds. C. Chemello, L. Brambilla, E. Joseph, Neuchâtel (Switzerland), 408-415.

[12] Degrigny, C. (2007) Examination and conservation of historic and archaeological metal artefacts: a European overview, in Corrosion of metallic heritage artefacts, Dillmann, P. et al. (eds), EFC 48, Woodhead Publishers, 1-17.

[13] Degrigny C., Gaspoz C., Rosselet A., Boissonnas V., Jeanneret R. and Bertholon R. (2016) The MIFAC-Metal Online project: developing a Decision Support System for locally invasive diagnosis of heritage metals, in METAL 2016, proceedings of the ICOM-CC Metal WG interim meeting, eds. R. Menon, C. Chemello and A. Pandya, New Dehli, (India), 220-227.

[14] Bertholon, R., et al. (1998). Corrosion du rouleau de cuivre de Qumrân et localisation de la surface originelle. Metal 98 International Conference on Metals Conservation, Draguignan, James and James

[15] Bertholon, R. (2000). La limite de la surface d'origine des objets métalliques archéologiques. caractérisation, localisation et approche des mécanismes de conservation. UFR03 Art et Archéologie. Paris, Université Paris 1 Panthéon-Sorbonne: 419p.

[16] Bertholon, R. (2001). The location of the original surface, a review of the conservation literature. Metal 2001 Proceedings of the ICOM-CC Metals Working Group, Santiago, Chile 2-6 April 2001, Western Australian Museum.

[17] Bertholon, R. (2001). "Characterisation and Location of the Original Surface of Corroded Archaeological Objects." Surface Engineering 17(3): 241-245.

[18] Bertholon, R. (2007). Archaeological metal artefacts and conservation issues : long-term corrosion studies. Corrosion of metallic heritage artefacts. P. Dillmann, G. Béranger, P. Piccardo and H. Matthiesen. Cambridge, Woodhead Publishing Lmd: 31-40.

[19] Bertholon, R. (2002). "Proposition d'une méthode de description de la corrosion des objets métalliques archéologiques : schéma général." Cahier Technique de Conservation-Restauration des biens culturels 9: 56-65.

[20] Bertholon, R., et al. (2003). Comprehensive approaches of corroded conditions for archaeological iron artefacts : filling the gap between macroscopic observation and microanalysis for conservation diagnosis. International Conference on the Application of Raman Spectroscopy in Art and Archaeology, Ghent.